Wholesale Commercial Snack Food Equipment: Cost-Saving Strategies

In the competitive world of snack food businesses, having efficient and cost-effective equipment is crucial for success. In this blog, we will explore cost-saving strategies for purchasing and operating wholesale commercial snack food equipment, with a special focus on MARCHEF, a renowned manufacturer in the industry. By implementing these strategies, snack food businesses can optimize their operations, enhance profitability, and provide delightful treats to their customers.

I. Understanding the Importance of Cost-Saving Strategies

Before delving into specific cost-saving strategies, it is essential to recognize the significance of making wise financial decisions for snack food businesses. In the fiercely competitive market, every penny saved can make a difference. By investing in cost-effective equipment and optimizing operational expenses, businesses can allocate resources more efficiently and enhance their overall profitability.

II. Choosing the Right Manufacturer: MARCHEF

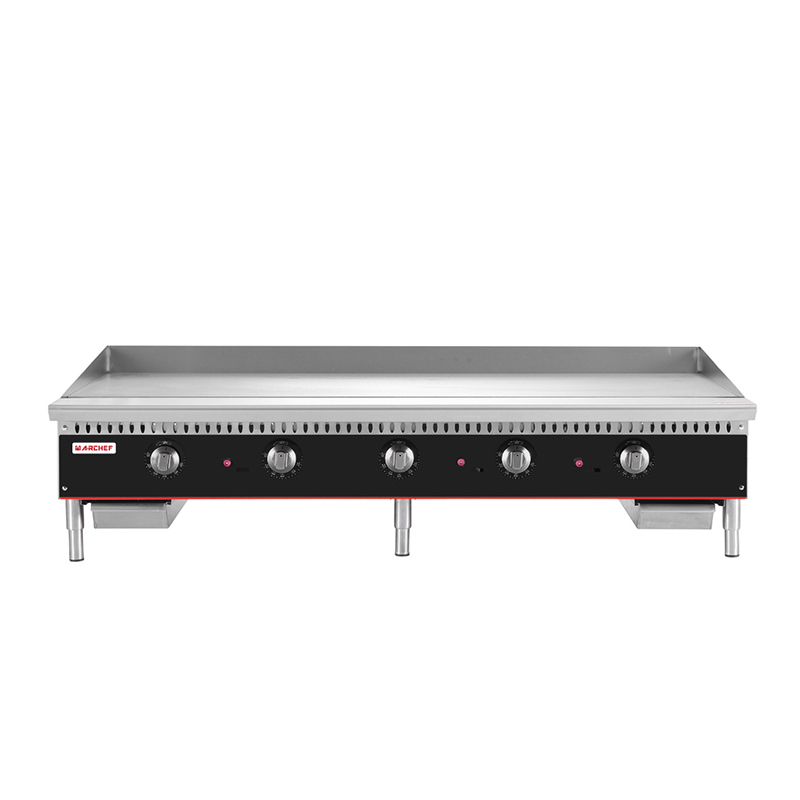

Selecting the right manufacturer for snack food equipment is the foundation of any cost-saving strategy. MARCHEF has emerged as a reputable name in the industry, renowned for its high-quality and innovative equipment solutions. With a wide range of snack food equipment, MARCHEF offers cutting-edge technology designed to improve efficiency and reduce costs. Collaborating with a trusted manufacturer like MARCHEF ensures that businesses are equipped with reliable and durable machinery.

III. Opting for Energy-Efficient Equipment

Energy costs constitute a significant portion of operational expenses. By investing in energy-efficient snack food equipment from MARCHEF, businesses can reduce their carbon footprint and cut down on utility bills. Energy-efficient machines not only save money but also demonstrate a commitment to sustainability, which resonates with environmentally conscious consumers.

IV. Bulk Purchasing and Wholesale Deals

When procuring snack food equipment, businesses can negotiate better deals by opting for bulk purchases and exploring wholesale options with manufacturers like MARCHEF. Buying in bulk often comes with cost advantages and discounts, allowing businesses to acquire the necessary equipment at a more affordable price.

V. Long-Term Reliability and Maintenance

Prioritizing the longevity and reliability of snack food equipment can lead to substantial cost savings in the long run. MARCHEF’s equipment is known for its durability and low maintenance requirements, reducing the need for frequent repairs or replacements. Regular maintenance and servicing also play a critical role in extending the lifespan of the equipment and avoiding unexpected breakdowns.

VI. Flexible Financing Options

Understanding the financial constraints of starting or expanding a snack food business, MARCHEF provides flexible financing options to assist customers in acquiring the necessary equipment without straining their budgets. These financing plans enable businesses to make affordable monthly payments while benefiting from top-notch equipment.

Factory Price High-Quality 6 Baskets Electric Pasta Cooker for Sale

I. Precise Temperature Control:

The MARCHEF pasta cooker is equipped with two temperature controllers, allowing you to set and maintain the desired cooking temperature efficiently. With a range from 30 to 110 degrees Celsius, you have full control over the cooking process, ensuring that your pasta and other foods are cooked to perfection consistently. This level of precision is essential in any commercial kitchen, where timing is crucial for delivering top-notch dishes.

II. Intuitive Indicators:

To make the cooking process even more manageable, the MARCHEF pasta cooker features power and heating indicator lamps. The power indicator lamp lets you know when the cooker is turned on, while the heating indicator lamp indicates when the cooker is actively maintaining the set temperature. These simple yet effective indicators ensure that you’re always aware of the cooking status, reducing the risk of mishaps during a busy cooking session.

III. Large-Capacity with 6 Baskets:

Efficiency is paramount in a commercial kitchen, and the MARCHEF pasta cooker meets this requirement by being equipped with six baskets. This large-capacity setup allows you to cook a variety of pasta or other food items simultaneously, saving you time and energy. Whether it’s a bustling restaurant or a busy catering event, this cooker’s ability to handle a high volume of food makes it a true asset for any professional chef.

Extending the Life of Wholesale Commercial Snack Food Equipment: Maintenance Tips from MARCHEF

I. Understanding the Importance of Regular Maintenance

Maintaining snack food equipment is not just about keeping it clean; it’s about maximizing its lifespan and optimizing efficiency. Regular maintenance prevents costly breakdowns, minimizes downtime, and ensures food safety and quality. By adhering to recommended maintenance practices, snack food businesses can save money in the long run and maintain a competitive edge.

II. Cleaning and Sanitizing Guidelines

MARCHEF emphasizes the significance of proper cleaning and sanitization. Regularly cleaning equipment not only improves food safety but also enhances the taste and presentation of snacks. Snack food equipment, such as fryers, ovens, and food processors, should be cleaned thoroughly after each use. Using manufacturer-approved cleaning agents and following the recommended cleaning schedule is vital.

III. Lubrication and Calibration Procedures

Neglecting lubrication and calibration can lead to premature wear and tear, affecting the equipment’s performance. MARCHEF advises users to follow their equipment’s maintenance manual for lubrication schedules and procedures. Additionally, regular calibration of temperature settings and timers ensures precise cooking times, consistency, and optimal results.

IV. Inspection and Early Detection of Issues

Proactive inspection is an essential aspect of equipment maintenance. Regularly inspecting the equipment helps identify any signs of wear, loose parts, or potential issues early on. Timely detection allows for prompt repairs, reducing the risk of major breakdowns and costly replacements.

V. Replacement of Worn or Damaged Parts

MARCHEF recommends using genuine replacement parts for their equipment. Using non-authentic parts might compromise performance, safety, and warranty coverage. Replacing worn or damaged parts with authentic ones ensures the equipment operates at its best and extends its lifespan.

VI. Employee Training on Maintenance Procedures

A well-trained staff plays a significant role in equipment maintenance. MARCHEF encourages snack food business owners to conduct regular training sessions for their employees. These sessions should cover proper cleaning techniques, basic troubleshooting, and safety protocols to ensure the equipment is handled with care.

Ⅶ. Scheduling Professional Maintenance Service

Even with regular in-house maintenance, professional servicing is essential. MARCHEF advises scheduling regular maintenance check-ups with authorized technicians. These experts have the knowledge and tools to detect and resolve potential problems that might go unnoticed during routine inspections.

Conclusion

Wholesale commercial snack food equipment can be a game-changer for businesses aiming to maximize efficiency and profitability. With MARCHEF as a trusted manufacturer, implementing cost-saving strategies becomes more accessible. By choosing the right equipment, optimizing energy usage, and embracing long-term reliability, snack food businesses can create a winning recipe for success. Embrace these strategies, and watch your snack food business thrive while serving up delectable treats to your delighted customers.

Contacts Us

Please feel free to contact our friendly reception staff for any product equipment questions!